- Pre-sale:

- YADE will provide you with suitable customized solutions

- In-sale:

- YADE will keep updating the process and details of your order to you.

- After-sale:

- YADE provide installation training and instruction

3) Detailed instructions.

Anyone who buys products and meets any after-sales problems can contact with YADE at any time.

Φ 400 difference between axial and centrifugal fans | Low Noise High Airflow | Using in Dehumidifier

Product description:

1.The axial flow fan drives the gas along the axial direction by the rotation of the blade. The centrifugal fan is transported by centrifugal force generated by impeller rotation.

2. Axial flow fan rotor is generally exposed installation, large volume; The rotor of the centrifugal fan is closed and small in size.

3.The wind pressure generated by axial flow fans is very low, but the air volume is large; Centrifugal fans can produce high wind pressure (up to 0.2MPa), and the air volume is generally small.

4. The arrangement of centrifugal fan is simple, and the wind volume and breeze pressure are large. The axial fan does not reverse the flow direction of the medium in the air duct, and is convenient to install. It is installed in the air duct or the front end of the air duct outlet.

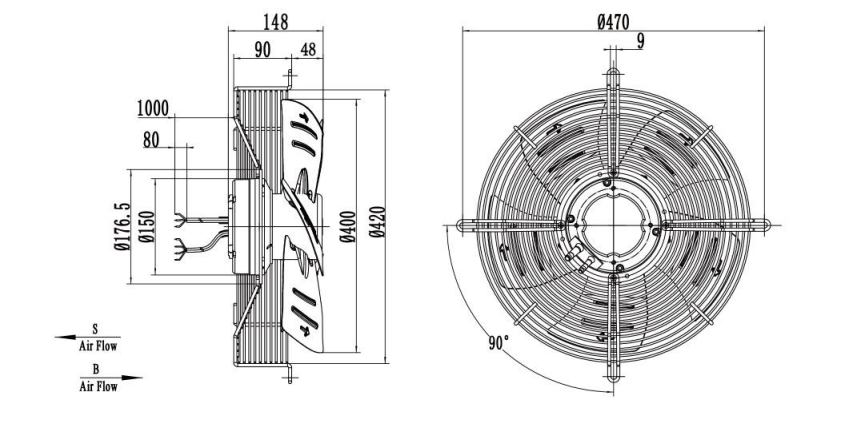

Working Voltage(V) | 200 ~ 277 | DiameterΦ( mm ) | 400 |

Power (W ) | 430 | Noise ( dB) | 69 |

Speed ( RPM ) | 1710 | Temperature(°C) | -25℃ ~ 60℃ |

Type |

Rated voltage V

|

Working Voltage V

|

Current

A |

Power W | Speed RPM | Noise dB (A) | |

EC92-A400 | 230 | 200 - 277 | 2.8 | 430 | 1710 | 69 | |

- *Title

- *Content

- ECM Motor and Shade Pole MotorSep 22,2025This is an excellent question that gets to the heart of efficiency and cost in modern appliances. Here’s a detailed breakdown of the advantages and disadvantages of Electronically Commutated Motors (ECM) compared to Shaded Pole Motors.

- The fan used on the evaporator, the key point of attention.Sep 11,2025Quantify: Don't guess airflow and pressure. Match: Select the fan to operate at its BEP for your specific system curve. Verify: Measure airflow at startup and adjust. This is the single most important commissioning task. Maintain: Keep it clean and balanced. The performance degradation is quadratic with speed reduction due to fouling. Evaluate Lifecycle Cost: The higher efficiency of an ECM motor often justifies its cost through operational energy savings, especially in variable load application

- Phone

- +86-158-67128766

- Skype

- belinda.zhou.dental

- sales01@yadefan.com sales02@yadefan.com